Description

REYCO Systems Inc. specializes in innovative food processing solutions designed to enhance efficiency, reduce waste, and improve product quality. Our advanced fluid removal technology recovers and filters valuable processing fluids, while our air handling units ensure clean, temperature-controlled environments. We offer pneumatic conveying systems for safe, damage-free transport and UVC decontamination for chemical-free sanitization. With high-performance solutions like Watervac and Ecomiser Elite, REYCO Systems helps food processors achieve sustainability and cost savings. Contact us today to optimize your operation!

Reviews

Opening hours

Products And Services

-

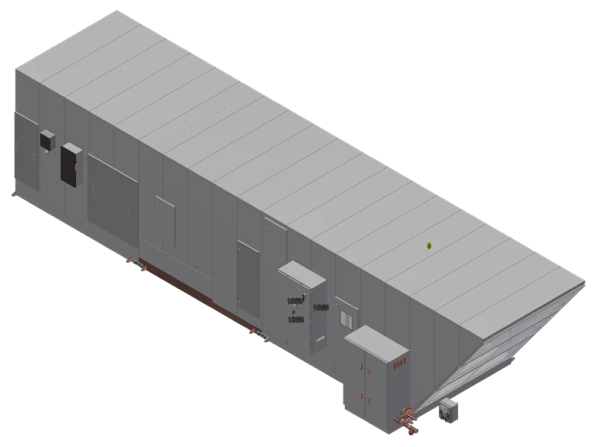

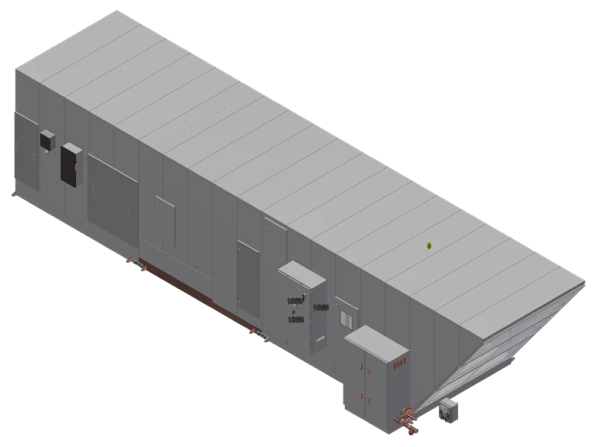

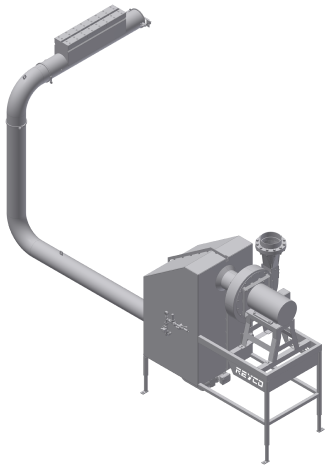

Food Processing Air Make-Up Unit

REYCO Systems® Air Make-Up Units (AMU) are manufactured to the highest quality standards to operate in some of the most difficult food processing environments. We established our reputation in the extreme conditions of the French fry industry and continue to build on that success.

-

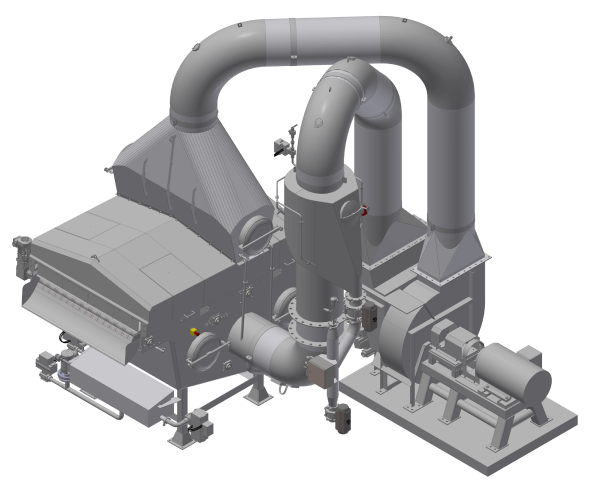

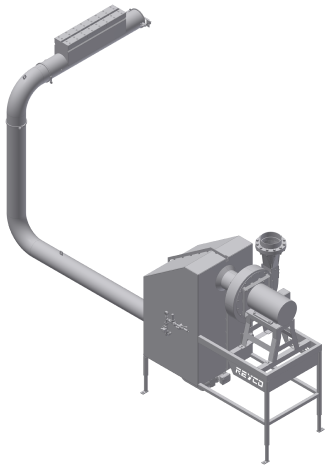

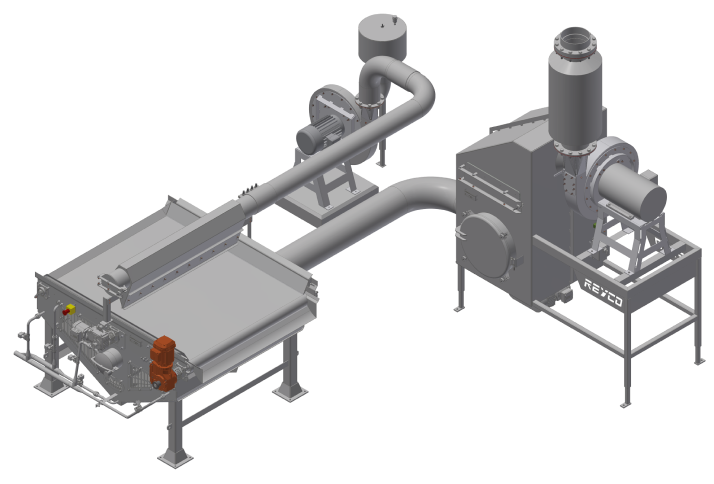

EcoMiser for Food Processing Oil Recovery

REYCO Systems® proudly announces the EcoMiser® Elite Oil Removal System with a revolutionary swirl tube design, eliminating bulky cyclones and reducing crumb build-up and fire risks. The system cuts floorspace by 40% and offers flexible installation options.

-

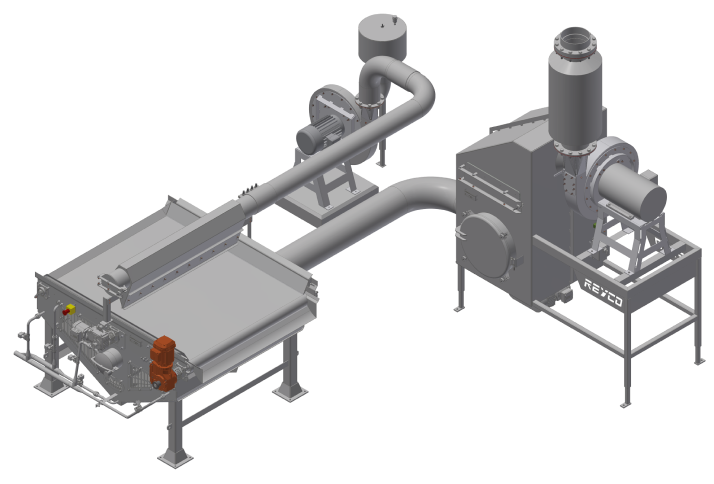

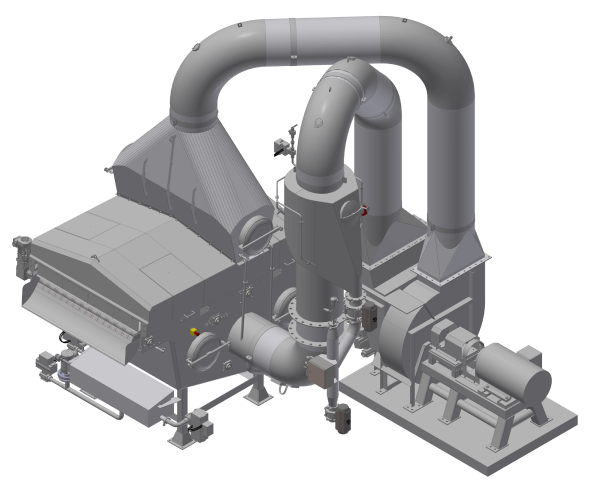

EcoVac for Food Processing Water Recovery

The REYCO EcoVac™ was designed for water removal in the fresh-cut foods industry and has expanded to fresh-cut fruits and dehydrated facilities. It efficiently dewaters products like packaged salads, cabbage, carrots, radishes, and potato salad, while offering evaporative cooling to reduce temperatures before freezing.

-

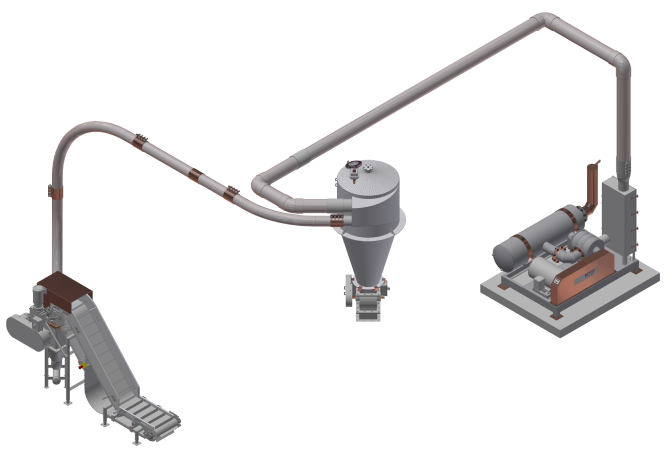

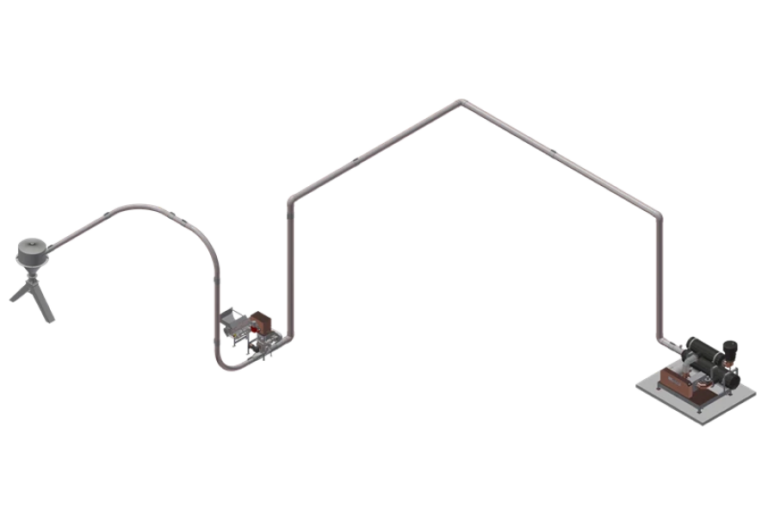

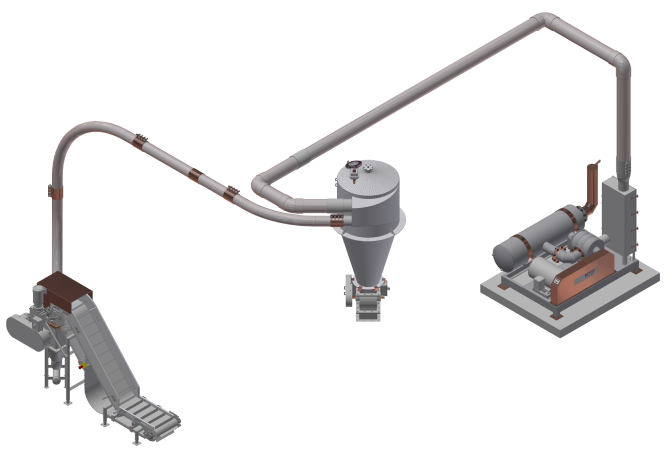

Negative Pneumatic Conveying System

REYCO Systems Negative Pneumatic Conveying offers advanced technology with key benefits like no line loss, no cross-contamination, and fewer moving parts compared to belts or bucket conveyors. USDA-approved designs meet stringent sanitary requirements, making these systems ideal for allergen-laden products.

-

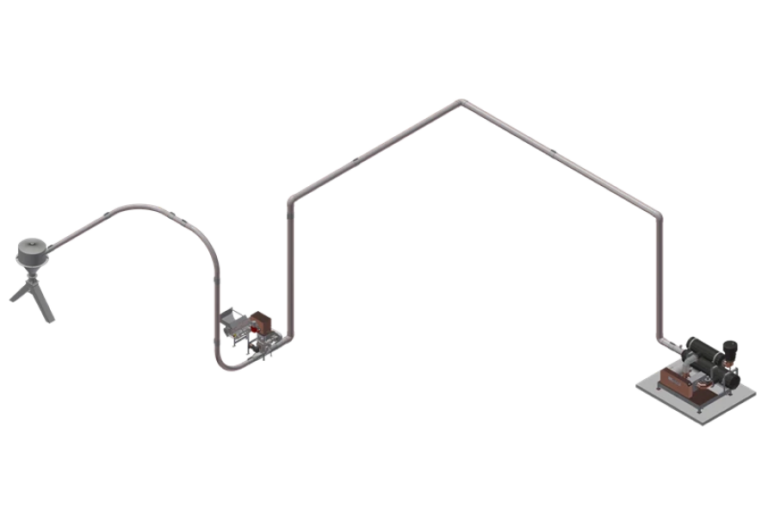

Positive Pneumatic Conveying System

The REYCO Positive Pneumatic conveying system offers a more efficient, cost-effective alternative. A blower pressurizes a waste pipe that runs under the cutting deck, in the foundation, or along the roof. Waste is fed into the system through rotary airlocks and quickly transported to a truck or bin for removal—without the need for water, conveyors, or lift trucks. REYCO also provides a full line of related components to ensure smooth waste handling and disposal.

-

UV Hood for UVC Food Processing

REYCO Systems’ UVC Hoods deliver effective sanitation solutions for food processing, designed for maximum UVC exposure. They can be installed over or under the conveyor line, allowing easy access for cleaning, bulb replacement, and maintenance. Built from heavy-duty stainless steel or aluminum, these hoods feature watertight electrical components, making them suitable for wash-down environments.

-

Water Vac for Vacuum Moisture Removal

Since 1990, the REYCO WaterVac® has been a staple in the vegetable and fresh-cut industries, solving clumping issues and even pre-cooling in some cases. It can extend freezer defrost cycles by up to 50%, significantly reducing energy costs and increasing uptime. For example, processors needing an eight-hour defrost can often extend this to twelve hours.

Categories

Agriculture Supplies & Equipment(208)795-5700 (208)-795-5700 +12087955700

Map 1704 Industrial Way

Loading map...